By William D. Nesse

2012 marks the Diamond Jubilee of the coronation of Queen Elizabeth II of England. The Imperial State Crown she wore after her coronation and the Soverign’s Sceptre with cross that she held contain two of the most remarkable gems in the world. Both were cut from the Cullinan diamond, reportedly the largest diamond ever found (3106 carats/0.62 kg). Cullinan I or Star of Africa (530.2 carats) is the largest of the nine gems cut from the Cullinan and it is now part of the Soverign’s Sceptre with cross. The Cullinan II, or Lesser Star of Africa (317.4 carats), is mounted on the Imperial State Crown.

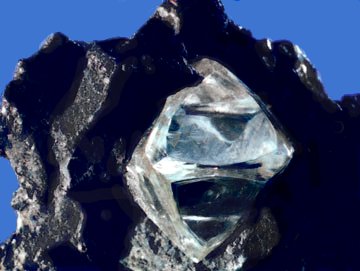

These exceptional gems are samples of diamond, a mineral made entirely of carbon, the sixth element on the periodic chart. The crystal structure is relatively simple; each carbon atom chemically bonds to four neighboring carbon atoms using very strong covalent bonds (solid lines) that place the carbon atoms just 1.54 angstroms apart. This continuous and systematic three-dimensional framework of carbon atoms forms a cubic building block (dotted lines). The external shapes of diamond crystals reflect the three-dimensional symmetry of this framework of carbon atoms. Natural diamonds typically form cubes, octahedrons, or rhombic dodecahedrons. An octahedron is shown here (photo from U.S. Geological Survey). The strong chemical bonds account for diamond’s distinctive physical properties including hardness, brilliance, fire, and ice.

Diamond is the hardest known material. This hardness, coupled with its great strength, makes it extremely valuable as an industrial mineral. It is extensively used to cut, grind, and polish other materials. The saw blades used to cut bricks, concrete, rock, and many other materials are studded with small diamonds. Grinding wheels impregnated with numerous fine diamonds, and slurries and pastes containing fine diamond particles, are used to produce a mirror-like finish on many products. A notable example is the semiconductor industry, where diamond saws and abrasives are used to prepare silicon wafers that serve as the substrate for myriad semiconductors that are an integral part of our lives. Nearly 900 metric tons of diamonds — worth $1.65 to $2.5 billion — are used worldwide each year for industrial purposes.

Brilliance and fire are important for diamond’s role as a gemstone. Because of its high density, diamond has a very high index of refraction, which is a measure of how much the path of light can be bent when it enters the diamond. One consequence of the high index of refraction is that the gem has a brilliant luster. Diamond also has very high dispersion, which means that light at the violet end of the spectrum is bent significantly more than light at the red end of the spectrum. The diagram to the right shows how this works for light containing the full spectrum of colors that enters a diamond gem from above. The violet light is bent more on entering the diamond than the red light, so after reflecting twice from the internal surfaces of the gem, the violet and red light are significantly separated when they exit the top of the gem. Gems are cut so that light that enters from all directions is reflected multiple times from inside surfaces before exiting and reaching the viewer’s eyes. The long paths allow the different parts of the visible spectrum to be separated so that the individual colors can be seen as the “fire” that makes diamonds so desirable.

Brilliance and fire are important for diamond’s role as a gemstone. Because of its high density, diamond has a very high index of refraction, which is a measure of how much the path of light can be bent when it enters the diamond. One consequence of the high index of refraction is that the gem has a brilliant luster. Diamond also has very high dispersion, which means that light at the violet end of the spectrum is bent significantly more than light at the red end of the spectrum. The diagram to the right shows how this works for light containing the full spectrum of colors that enters a diamond gem from above. The violet light is bent more on entering the diamond than the red light, so after reflecting twice from the internal surfaces of the gem, the violet and red light are significantly separated when they exit the top of the gem. Gems are cut so that light that enters from all directions is reflected multiple times from inside surfaces before exiting and reaching the viewer’s eyes. The long paths allow the different parts of the visible spectrum to be separated so that the individual colors can be seen as the “fire” that makes diamonds so desirable.

Diamonds are sometimes referred to as “ice” because they seem cold to the touch. The diamonds are not actually colder than their surroundings. The perception of cold is a consequence of the strong covalent bonds that give diamond unsurpassed thermal conductivity at room temperature. It conducts heat four to seven times faster than metals such as gold, silver, or copper. When a diamond at room temperature is touched to the lip, which is quite sensitive, body heat is conducted into the diamond far faster than heat is conducted into a gold ring that is touched to the lip. Our brain interprets the rapid loss of heat to the diamond as though the diamond is colder than the gold ring, even though they are the same temperature. This property is just an interesting curiosity as far as diamond’s use as a gem is concerned, but it has important industrial applications. For example, diamonds make superior heat sinks to control the temperature of microprocessors in computers and other electronics, and its use for this purpose is increasing as costs are reduced.

The large majority of natural diamonds are from volcanic rocks, called kimberlite and lamproite, that are derived from 150 to 200 km below the Earth’s surface. The extremely high pressures found at that depth are required to allow diamond to crystallize rather than become graphite, the low-pressure form of carbon. Diamonds are mined from these volcanic rocks, and from sedimentary deposits derived from them, on every continent except for Europe and Antarctica. In 2009, 129 million carats of diamonds were mined worldwide, of which 57% were gem quality. The remainder were used for industrial purposes. The price for typical gems is between $800 and $12,000 or more per carat depending on size and quality. Russia is the largest single producer, with about 25% of the total.

Commercial production of synthetic diamonds began nearly 60 years ago. Because synthetic diamonds can be produced in large quantities with very tight control over quality, almost 99% of the nearly 900 metric tons of diamonds used for industrial purposes are synthetic. While gem-quality diamonds can be synthesized, they command far lower prices than similar natural samples. Most synthetic diamonds are made using very high temperatures and pressures, and sizes are smaller than a few carats. A relatively new process called chemical vapor deposition operates at low pressures and holds the promise of being able to produce large pure samples. This should enable an expanded range of technological applications.

As Oxford University Press celebrates the Diamond Jubilee of Queen Elizabeth II, it is worth noting just how remarkable diamonds, for which the jubilee is named, really are. They make lovely gems that symbolize the strength and resolve of the British monarchy. But perhaps more importantly, their unsurpassed physical properties make them a critical industrial commodity that supports the commerce and industry upon which modern society and culture depend.

As Oxford University Press celebrates the Diamond Jubilee of Queen Elizabeth II, it is worth noting just how remarkable diamonds, for which the jubilee is named, really are. They make lovely gems that symbolize the strength and resolve of the British monarchy. But perhaps more importantly, their unsurpassed physical properties make them a critical industrial commodity that supports the commerce and industry upon which modern society and culture depend.

Dr. William D. Nesse is Professor Emeritus of Geology in the School of Earth Sciences and Physics at the University of Northern Colorado and the author of Introduction to Mineralogy and Introduction to Optical Mineralogy. He is also a guitarist who plays with the informal Northern Colorado Guitar Ensemble and a luthier specializing in classical guitars.

Subscribe to the OUPblog via email or RSS.

Subscribe to only articles about environmental and life sciences on the OUPblog via email or RSS.

View more about this book on the ![]()

![]()

[…] Diamond Jubilee in June: Composing for the Diamond Jubilee, How to Write Music Fit for a Queen, Diamonds, Royal quotations past and […]